Burner Technology

The use of technical SiC ceramics in thermal process technology makes a substantial contribution to reducing emissions and exploiting efficiency potential for direct and indirect heating.

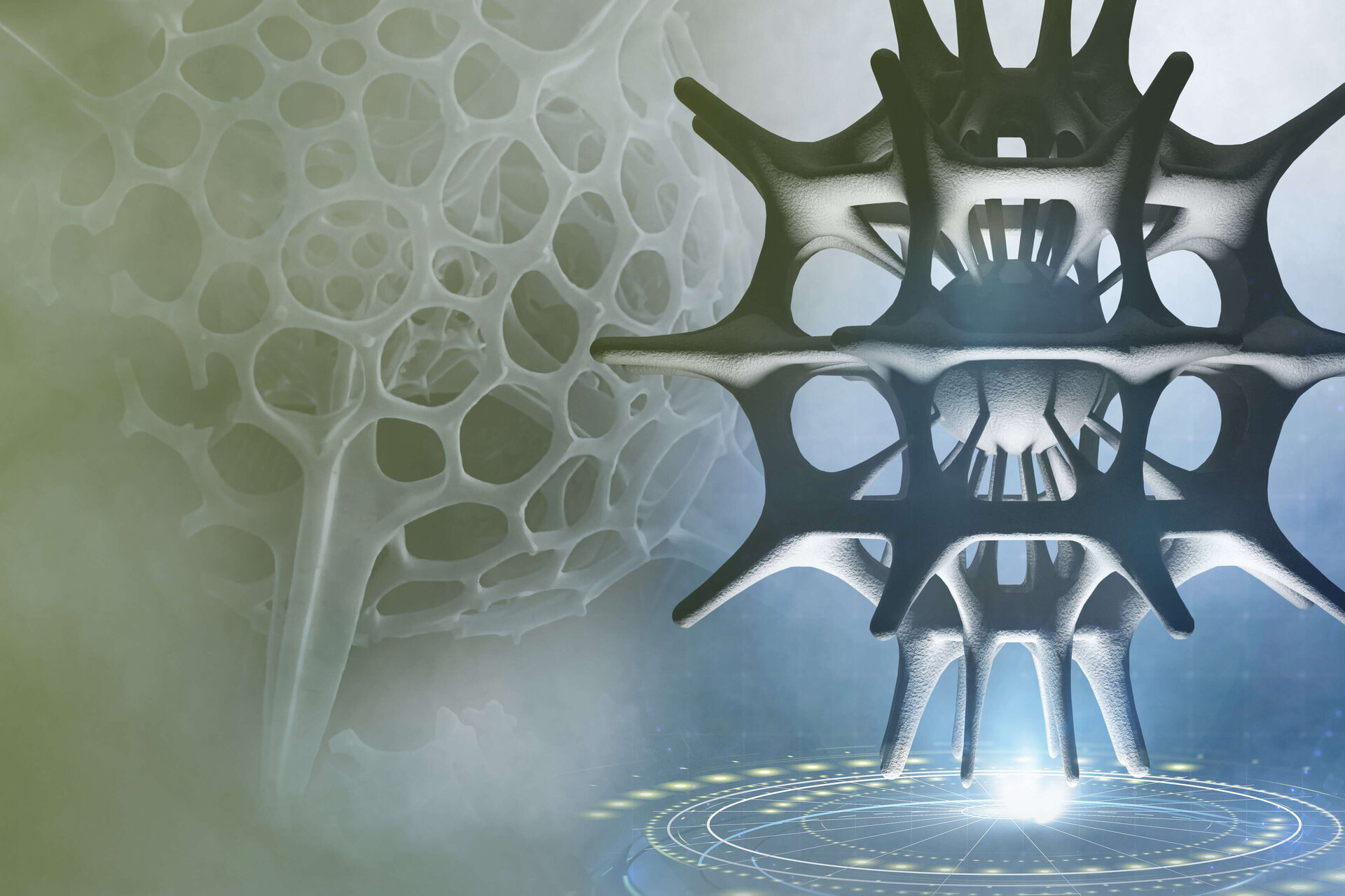

Temperature-resistant, media-resistant, abrasion-resistant, extremely hard and bulletproof – technical ceramics from Schunk Ingenieurkeramik combine valuable characteristics like no other material. This allows us to offer solutions that set new standards for industrial applications. The internationally unique IntrinSiC® is our innovative production solution that allows components to be fabricated from silicon carbide by 3-D printing that were previously impossible due to their complexity and size. Together with our customers, we develop tailored, cutting-edge products for furnaces and plants, tribological systems such as pumps and compressors, and laboratory ceramics and ballistics protection.

Discover the different materials & coatings from Schunk Technical Ceramics. With innovative solutions for (almost) every area of application, we will find exactly the material that will take you further.